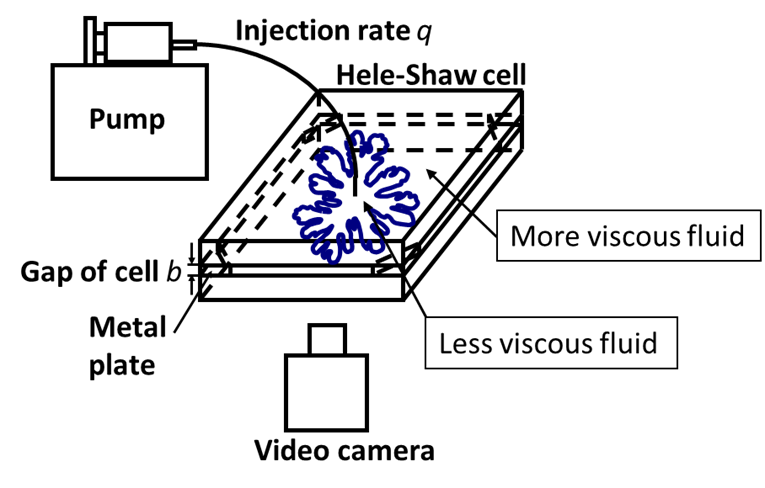

When a less viscous fluid displaces a more viscous one in porous media, VF occurs as introduced in "Viscous fingering" section. Then, what happens when a chemical reaction occurs at the interface between the displcing and displaced fluids during VF experiments?

The answer is still explored because the effect of flow and the property of the product are very complicated. We have report an interesting result occuring when the product by chemical reaction has viscoelasticity.

It is expected that VF patterns are normally changed as the intensity of viscoelasticity of the product increases when the viscosity contrast is the same.

In fact, sometimes the viscous fingers become thinner with increase in the viscoelasticity and sometimes thicker (finally circular) with increase in viscoelasticity.

VF patterns under various pH conditions

The above figure shows the VF results, where we discovered the viscoelasticity of the product can be changed maintaining the viscosity contrast by changing pH condition of the displaced fluid.

The viscoelasticity at the interface is measured and showed below. The figure shows the intensity of the viscoelasticity increases with the increase in pH. However, VF patterns are changed.

For example, the viscous fingers are getting thinner with increase in pH at the range of 10-12 and the fingers become thicker with increase in pH at the range of 12-13.

Interfacial rheological measurement

G' represents strage modulus (corresponding to elasticity) and G'' represents loss modulus (corresponding to viscosity).

We have reported that our suggesting new model can explain the mechanism, which cannot be explained only by the viscoelasticity.

We study the unkown phenomena by experiments, numerical simulation and theoretical study because the unxplored phenomena and theories in VF study with chemical reactions exits like this case.

Sae Hirano, Yuichiro Nagatsu, and Ryuta X. Suzuki

Reversal of effects from gel production in a reacting flow dependent on gel strength

Phys. Rev. Fluids, 7, 023201(2022)